STORING

Keep in a dry and closed environment.

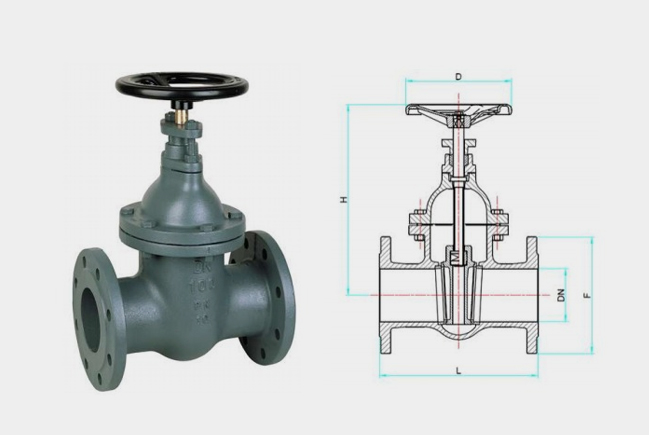

MAIN CHARACTERISTICS

Face-to-face length according to EN 558-1, basic series 15

Flanged according to EN 1092-2 PN16 with raised face

Inside screw thread clockwise closing, adjustable stuffing box

Minimal pressure drop

Hydrostatically tested according to EN 12266-1: Test type P11-P12 Rate A

Pressure Equipment Directive 2014/68/UE Group 2

100% full bore

Pressure Equipment Directive 2014/68/UE Group 2

Gate valves are bi-directional and can be installed in any position. However, the preferred orientation is

with the stem pointing vertically upwards.

RECOMMENDATIONS

Before carrying out maintenance, or dismantling the valve, be sure that the pipes, valves and liquids have

cooled down, that the pressure has decreased and that the lines and pipes have been drained in case of

toxic, corrosive, inflammable or caustic liquids.

Temperatures above 50°C and below 0°C might cause damage to people.

INSTALLATION

- Handle with care. DO NOT weld the flanges to the piping after installing the valve

- Water hammers might cause damage and ruptures. Inclination, twisting and misalignments of the piping

may subject the valve to stress, once installed. It is recommended that elastic joints be used in order to

reduce these effects as much as possible. The disc must be partially open. The mounting can be made

with the stem axis in a horizontal or vertical position. - Verify maximum working pressure and limits of use. Place the valve between two flanges. While placing

the valve, ensure there is sufficient space in order not to damage the rubber. Do not mount seals

between valve and flanges. - Carefully clean the contact surface. DO NOT weld the flanges to the tube if the valve has already been

installed. - Tighten the bolts crosswise and progressively, in order to distribute the pressure equally before the body

and flanges come into contact with each other - Turbulences of the fluid might increase erosion and reduce the life-cycle of the valve. Install the valve at a

distance of at least 1 x DN upstream, and at a distance of 2-3 x DN downstream, away from fittings or

bends. Check that no other components of the piping interfere or create damage or malfunctioning. If

they do, a spacer should be inserted for the valve to operate correctly.

DISPOSAL

For valve operating with hazardous liquids(toxic, corrosive…) , if there is a possibility of residue remaining in

the valve, take due safety precaution and carry out required cleaning operation. Personnel in charge must

be trained and equipped with appropriate protection devices.

Prior to disposal, disassemble the valve and separate the component according to various materials. Please

refer to product literature for more information. Forward sorted material to recycling (e.g. metallic materials)

or dispose it, according to local and currently valid legislation taking into consideration the environment.

BODY STEM

Grey cast iron EN-GJL-250 EN 1561 Brass CW614N EN 12164

SCREW WASHER

Zinc plated carbon steel 8.8, EN ISO 4017 Zinc plated carbon steel EN 7092

BONNET MOTHER SCREW

Grey cast iron EN-GJL-250 EN 1561 Brass CB 754-S GM EN 1982

SEAT STUFFING BOX AND PACKING GLAND

Brass CB 754-S GM EN 1982 Grey cast iron, EN-GJL-250 EN 1561

WEDGE FINISHING

DN40 => DN65: Phenolic-oil resin

Brass CB 754-S GM EN 1982 with zinc-phosphate

DN80 => DN200: coating Grey Ral 7011

Grey cast iron

EN-GJL-250 EN 1561

TIE ROD HANDWHEEL

Zinc plated carbon steel 8.8 Grey cast iron, EN-GJL-250EN 1561

NUT GASKET

Zinc plated carbon steel 8.8 , EN ISO 4032 FASIT 205

PACKING

PTFE ASTM 4894